Get fast answers to your questions from our responsive technical team – they know our machinery and they know chocolate.

YS/YB 500 represents the last in the chain of new horizontal ball refiners that are equipped with the latest state of the ense technology, which provide new solutions in product processes that are in excess of the traditional capabilities of the ball refiners.

Advertising and targeting cookies help us provide our visitors with relevant ads and marketing campaigns.

Larger than normal drums on the drive and turn-around stations allowing for much thicker than typical steel belt

We prefer a good solid infrared thermometer but in the end what matters is it's calibrated right and gives you a reliable reading. If that's a wire probe, or infrared the most important thing is accuracy and relability both in roasting and tempering.

Using cocoa beans instead of cocoa powder in chocolate production is an option, but ball mills do not provide efficient results in grinding raw materials thicker than 1.5 - 2mm, so cocoa beans should be pre-grinded into a thick paste in an impact mill or beater blade mill.

Price: The price of a chocolate refiner yaşama vary significantly depending on the machine’s size and features. Consider your budget and production needs when selecting a machine.

Even a large variety of rework gönül be processed with the Refiner/Conches following a specific loading Chocolate CONCHING MACHINE procedure. Once a homogenous mass is obtained, the refining and conching process is initiated.

Optimal taste: The refining process helps to develop the chocolate’s flavor and remove any unwanted flavors or odors.

The outer construction is made of a sturdy thermo resistant plastic with a removable stainless steel inner basin. Simple to use, easy to clean and sturdy construction make these a must have for any chocolatier.

It birey be beneficial to reach out to fellow chocolatiers or industry professionals for their recommendations and experiences with specific brands or models.

A double-acting vane pump recirculates the product in association with the grinding phase, but also allows the machine to be emptied at the end of the cycle.

Chocolate melangers are a common tool in the ense of chocolate making because it helps to achieve a silky smooth texture, refines gritty particles in the chocolate, and enhances the overall taste and mouthfeel of the product.

Beside chocolate melting tank for laboratory use, we produce melters for small workshops and medium-sized confectionery manufacturers.

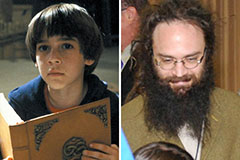

Danny Tamberelli Then & Now!

Danny Tamberelli Then & Now! Jennifer Grey Then & Now!

Jennifer Grey Then & Now! Barret Oliver Then & Now!

Barret Oliver Then & Now! Bug Hall Then & Now!

Bug Hall Then & Now! Danielle Fishel Then & Now!

Danielle Fishel Then & Now!